Robot staining gives the best quality results. Once properly programmed, an industrial painting robot will avoid drip, discrepancy, overspray, etc. Can apply material without releasing. Paint and / or coating is applied precisely and consistently. Industrial painting robots can provide exceptional parts accessibility. Robotic arms are not only thin and…

Grinding / deburring

Deburring robots remove material to remove burrs, sharp edges or fins from metal parts. Manufacturers use industrial deburring robots to increase the precision of the part being grounded or filed. Robotic deburring improves part quality because the robot can be programmed into each part and customized with the right to…

Bonding / Sealing

Bonding and Sealing robots can apply adhesives or sealants to almost any type of object. They are desirable due to the speed and accuracy of the application process. Automated technologies provide one-component and two-component robot bonding and sealing for a wide variety of products, markets and end users. Single Component…

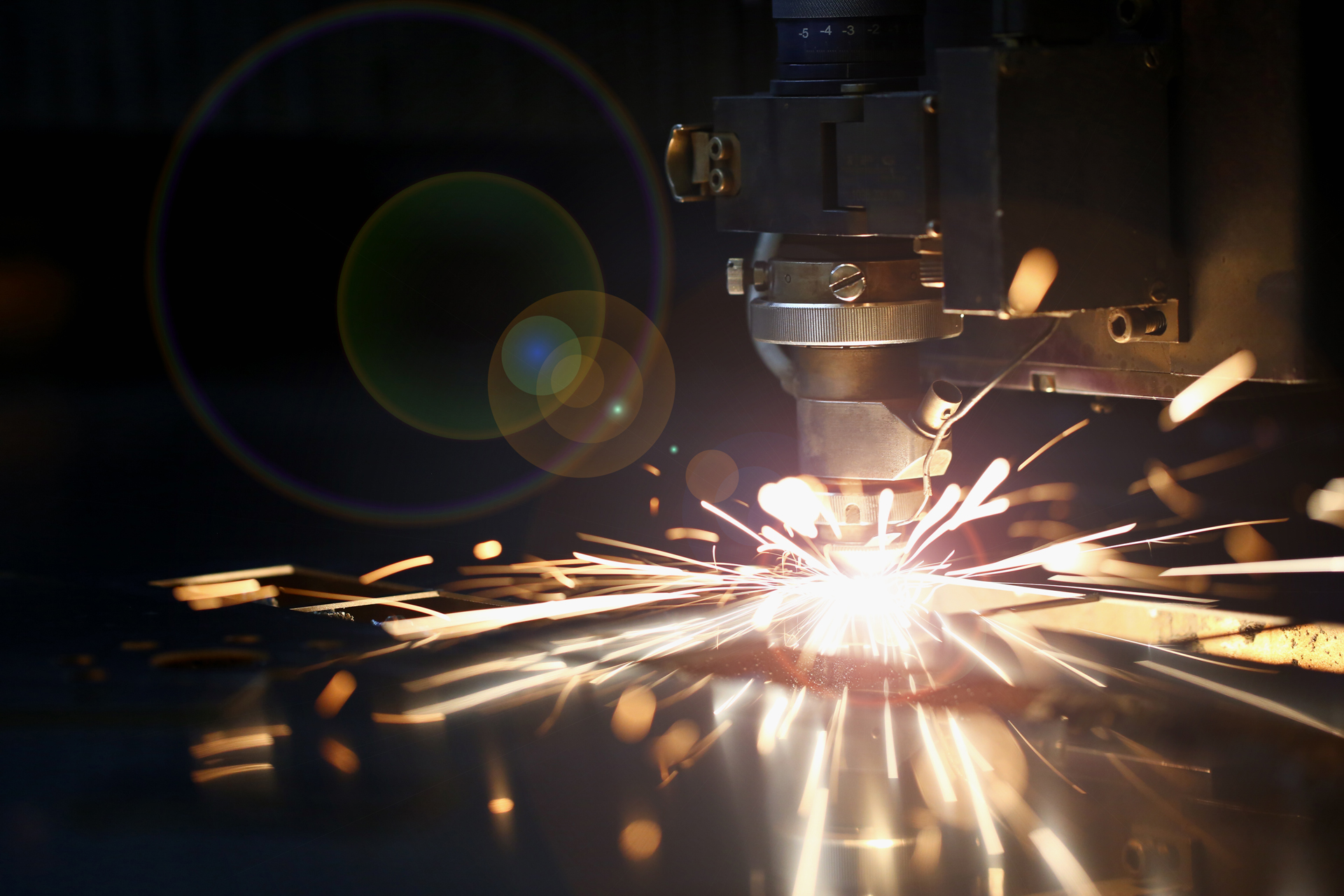

Plasma cutting

Robotic plasma cutting is a process that uses high-speed ionized gas known as plasma to heat and melt metals. The plasma mechanically blows the molten material to cut the workpiece. Plasma cutting is used to cut a steel or non-ferrous material less than 1 mm thickness. Using a robotic plasma…

Palletizing

Industrial palletizing means loading and unloading parts, boxes or other items on or off pallets. Automatic palletizer is an industrial robot palletizer that automatically handles the application. Palletizing robots can be seen in many industries, including food processing, manufacturing, and shipping. There is a wide variety of robotic palletizing machines…

Transport and Drop Applications

Robotic Pick and Drop automation increases production rates by speeding up the process of picking up parts and dropping them in new locations. With many end-of-arm tooling options, pick and release robots can be customized to suit specific production requirements. Moving large, small, heavy or difficult to use products can…

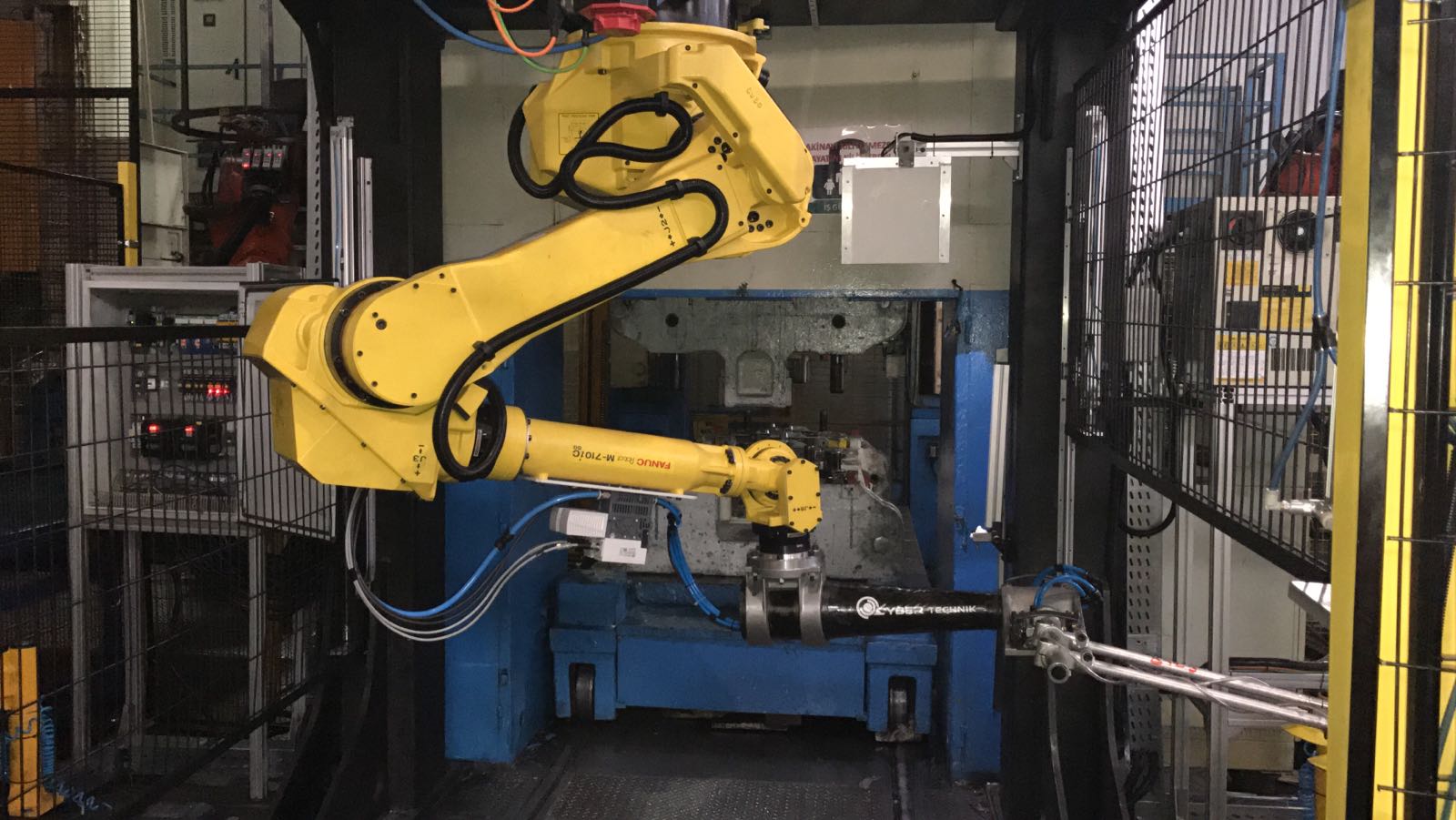

Press feeding

As a result of the researches, most accidents occur in presses. Thanks to robots, these accidents are minimized. 1-By using an independent robot between each press, the press line can be cut to the desired length and rotated in an L shape. 2-All operation parameters can be programmed easily by…

Arc welding

Arc welding uses electric arc between an electrode using consumable or non-consumable electrodes and a metal base. An arc welding robot uses a process that applies intense heat to the metal in a joint, causing the metal to melt and mix. Robotic arc welding machines are more consistent throughout the…

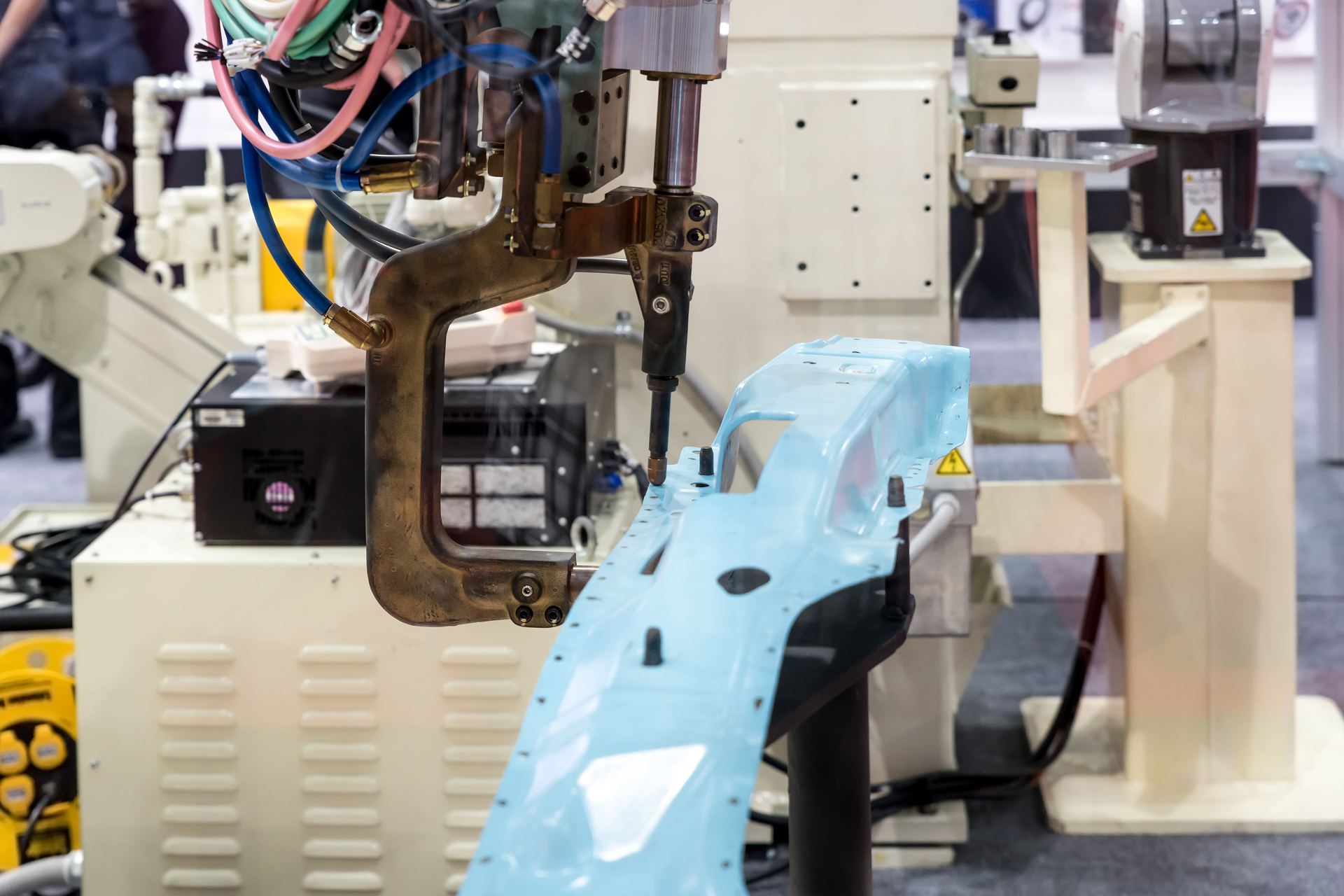

spot welding

Robot spot welding, a type of resistance welding, is the most common welding application found in the manufacturing field. When metals resist electric current, it binds thin metals. While widely used in the automotive industry for joining sheet metal frames, spot welding application has a variety of project uses. Automating…

Camera / vision

An industrial robot equipped with one or more cameras used to analyze and review images and provide a secondary data signal to the controller is a vision guided robot. These robot systems rapidly change the manufacturing process as it enables robots to be adopted and applied to the system. The…